In a primary, MIT scientists have 3-D printed a tiny six-legged robotic the use of a new method that entails printing strong and liquid materials at the same time.

the brand new approach lets in the team to routinely 3-d print dynamic robots in a single step, with out a assembly required, using a commercially-to be had 3-d printer.

“Our method, which we name ‘printable hydraulics,’ is a step closer to the speedy fabrication of purposeful machines,” said Daniela Rus, from Massachusetts Institute of era (MIT) in US.

“All you need to do is stick in a battery and motor, and you have a robot which can almost walk right out of the printer,” stated Rus.

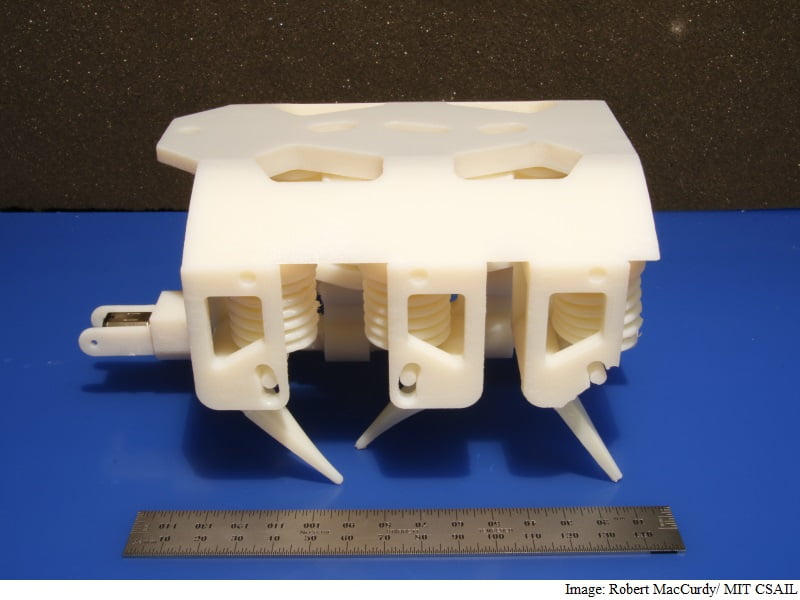

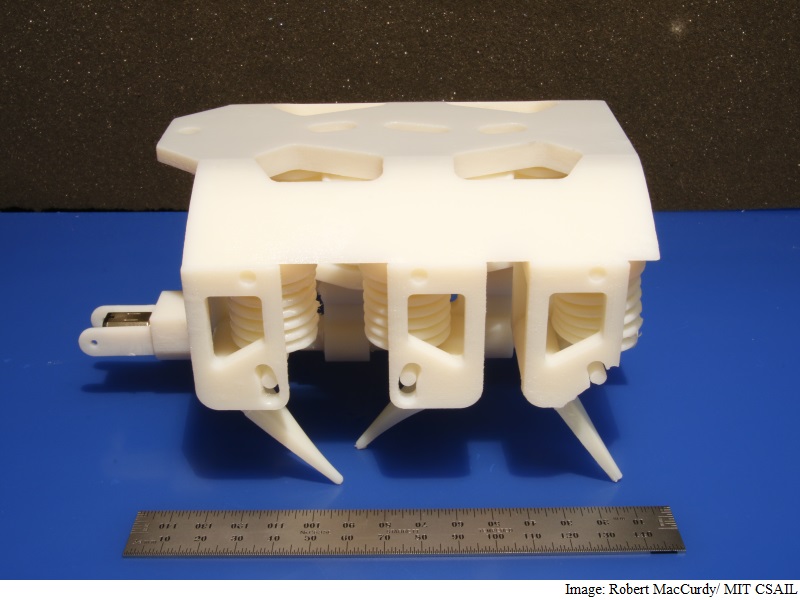

Researchers 3-D printed a tiny six-legged robot which can move slowly through 12 hydraulic pumps embedded inside its frame.

Printing drinks is a messy system, which means that most approaches require a further submit-printing step along with melting it away or having a human manually scrape it clean.

That step makes it difficult for liquid-based totally techniques to be employed for factory-scale manufacturing.

With “printable hydraulics,” an inkjet printer deposits person droplets of fabric which can be each 20 to 30 microns in diameter, or much less than half of the width of a human hair.

The printer proceeds layer-by way of-layer from the lowest up. For each layer, the printer deposits specific substances in distinctive parts, after which makes use of excessive-depth UV light to solidify all the materials except the liquids.

The printer makes use of more than one substances, even though at a more fundamental degree every layer includes a “photopolymer,” which is a strong, and “a non-curing cloth,” that’s a liquid.

“Inkjet printing lets us have eight specific print-heads deposit exclusive materials adjacent to one another, all on the same time,” said Robert MacCurdy from MIT.

“It offers us very excellent manipulate of material placement, that’s what permits us to print complicated, pre-stuffed fluidic channels,” he said.

some other venture with three-D printing beverages is that they often intervene with the droplets which can be purported to solidify.

to deal with that difficulty, the group published dozens of test geometries with exclusive orientations to determine the right resolutions for printing solids and drinks together.

MacCurdy said that printing both beverages and solids is even greater difficult with other 3D printing strategies, inclusive of fused-deposition modelling and laser-sintering.

The researchers 3-D revealed a small hexapod robotic that weighs approximately 1.5 pounds and is less than 6 inches lengthy.

to transport, a unmarried DC motor spins a crankshaft that pumps fluid to the robotic’s legs. aside from its motor and energy supply, every thing is printed in a unmarried step with no meeting required.

some of the robot’s key components are numerous set of “bellows” that are three-D revealed immediately into its frame. To propel the robotic, the bellows makes use of fluid strain that is then translated into a mechanical force.